Process improvement: Methods, steps, and real examples

Process improvement is a systematic way to work more efficiently. You reduce waste, prevent errors, and improve outcomes—without working more. In this short guide, you’ll learn what process improvement means, why it matters, which methodologies to consider, and how to run a practical improvement cycle. You’ll also see real process improvement examples and how tools like Gluu can help you document, run, and continuously improve processes.

Let’s start defining what it is.

What Is Process Improvement?

Process improvement is a disciplined approach to optimizing how work gets done. In other words, you examine a business process, find friction, and redesign the steps so you can deliver more value with less effort. That typically means fewer handoffs, fewer mistakes, shorter cycle times, and clearer ownership.

However, process improvement is not a one-time “fix.” The best teams treat it as an ongoing habit. They make small improvements often, measure impact, and standardize what works. Over time, that steady pace creates a durable competitive advantage through hundreds of small improvements.

Business Process Improvement

You’ll often see two terms used interchangeably: process improvement and business process improvement. The difference is mostly scope.

- Process improvement can apply to any process, including team-level workflows like invoicing, or incident handling.

- Business process improvement usually targets end-to-end, cross-functional processes that influence core performance—think order-to-cash, procure-to-pay, or hire-to-retire.

Even so, the logic stays the same. You clarify the goal, understand the current way of working, and improve the flow so your organization can deliver outcomes more predictably.

Why Process Improvement Matters

Processes – or a lack thereof! – quietly impact your cost-to-serve, customer experience, and employee satisfaction. When a process breaks, people compensate with fire fighting. That feels productive in the moment, yet it drains capacity and increases risk. Process improvement flips the script: you fix the system instead of relying on workarounds.

“A bad system will beat a good person every time.” — W. Edwards Deming

Here are common benefits you can expect:

- Less waste in time and material.

- More consistent quality because you build in checks where they matter and remove ambiguity.

- Faster response times by removing bottle necks.

- Higher productivity since people spend less time searching, waiting, and correcting.

- Stronger engagement when teams help shape “how we work” and see their ideas implemented.

To make this measurable, define a few KPIs that match your goal—cycle time, error rate, rework percentage, customer satisfaction, or cost per case. Then track them consistently so you can see whether the change actually helps.

Continuous Improvement Process

A continuous improvement process is the habit of making small, regular improvements instead of waiting for a big transformation project. That matters because work changes. Tools change. Regulations change. Customer expectations change. If your processes stay static, performance slowly erodes.

Continuous improvement works best when you make it easy for the people doing the work to contribute. For example, a frontline employee should be able to flag a bottleneck, propose a change, and see feedback from the process owner—without a month of meetings.

If you want to learn more about the ‘continuous’ part I suggest you read this post: The Case for Continuous Improvement

Top Process Improvement Methodologies

Methodologies give you structure. They also give teams a shared language, which reduces confusion and speeds up decisions. Still, you don’t need to be “pure” about any framework. Pick what fits your context, then adapt.

“Without standards, there can be no improvement.” — Taiichi Ohno

Lean

Lean focuses on maximizing customer value while eliminating waste. You look for delays, unnecessary approvals, duplicated work, and handoffs that add complexity. Then you redesign the flow so value moves faster.

Six Sigma (DMAIC)

Six Sigma is a data-driven approach to reduce defects and variation. The DMAIC cycle (Define, Measure, Analyze, Improve, Control) helps you move from symptoms to root causes—especially when quality and consistency matter.

Kaizen

Kaizen is part of the Lean philosophy and means “change for the better.” It emphasizes incremental improvements driven by the people closest to the work. It’s ideal when you want momentum, learning, and a strong improvement culture.

Total Quality Management (TQM)

TQM is a company-wide approach where quality becomes everyone’s responsibility. It connects leadership priorities, customer needs, and continuous improvement so quality is not “someone else’s job.”

Business Process Reengineering (BPR)

BPR is a more radical approach. Instead of improving step-by-step, you redesign a process from scratch. Use it when incremental changes won’t solve the problem—yet be careful, because major redesigns require strong change management.

Want to go deeper in this? Read this post: Top 5 process improvement methodologies

Steps in a Process Improvement Cycle

If you’re asking “what are the 7 steps of the improvement process?” this is a practical framework you can reuse. It stays simple, yet it covers what most teams miss.

- Identify the process you want to improve and define success. Start with a clear problem statement.

- Map the current process (“as-is”). Capture steps, roles, handoffs, and systems used.

- Analyze inefficiencies. Look for waiting time, rework, unclear inputs, and unnecessary approvals.

- Develop improvement strategies. Brainstorm options, then choose changes that fit capacity and risk.

- Plan and implement changes. Assign owners, update documentation, and support adoption with training.

- Monitor and measure performance. Track KPIs and gather user feedback so you can validate impact.

- Standardize what works. Update work instructions, clarify roles, and make the new way easy to follow.

Importantly, steps 2 and 7 often determine whether improvement sticks. A great idea fades fast if people can’t see the current way of working—or if the improved way never becomes the new standard.

Looking for a more in-depth explanation? Read Process improvement process steps: An introduction

Process Improvement Examples

Examples make process improvement concrete. Below are five common scenarios that show how small changes can create big results.

1) Automating repetitive manual tasks

If a team copies data between systems, the process will be slow and error-prone. Start by mapping where the data comes from and where it should end up. Then automate the transfer or simplify the data entry. As a result, you reduce defects and free up time for higher-value work.

2) Streamlining approval workflows

Approvals often pile up because ownership is unclear or because every exception needs a senior signature. Instead, define thresholds and empower the right roles to approve within guardrails. You keep control, yet you cut waiting time dramatically.

3) Improving quality checkpoints

Quality improves when checks happen at the right moment. Move checkpoints earlier, add clear acceptance criteria, and attach the relevant work instruction where people need it. That way, you prevent defects instead of detecting them late.

4) Reducing handoffs between teams

Every handoff increases risk. Information gets lost, context disappears, and accountability blurs. Combine steps when possible, clarify inputs and outputs, and make responsibilities visible. Even a small reduction in handoffs can increase speed and stability.

5) Enhancing data flows and dashboards

Teams often measure too much—or too little. Pick a few KPIs that reflect the process goal. Then create a simple rhythm: review results, decide actions, and document what changed. Over time, the dashboard becomes a learning tool rather than a reporting burden.

Tools & Technology for Process Improvement

You can improve processes with sticky notes and spreadsheets. Yet scaling improvement across teams gets hard fast. That’s where process improvement software helps. A strong platform lets you document processes, assign ownership, connect steps to work instructions, and keep everything current as the business changes.

In practice, look for tools that support:

- Process mapping that business users can understand and maintain.

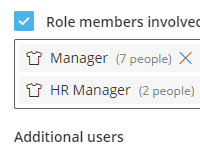

- Clear roles and ownership so work doesn’t disappear into shared inboxes.

- Collaboration through comments, feedback, and change suggestions.

- Version control and governance so improvements are auditable and standardized.

- Integrations so processes connect to the systems where work actually happens.

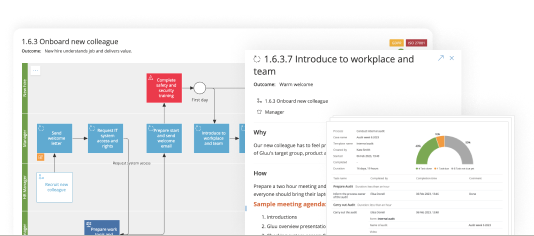

Gluu is designed as a people-friendly BPM platform that supports this end-to-end loop—from mapping, to execution support, to continuous improvement. For example, Gluu’s process improvement features focus on involving the people who do the work, so you can turn feedback into controlled changes instead of informal workarounds.

Examples of process improvement software features

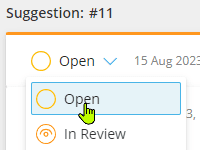

Change suggestion flow

Convert comments into change suggestions and manage approval before changes are implemented.

One-click change communication

Summarize changes and send automatic updates to relevant users by email when content is updated.

Try process improvement with Gluu

Sign up for a 30-day trial.

No credit card required.

FAQ – Process Improvement

What do you mean by process improvement?

Process improvement means systematically making a workflow more effective. You reduce waste and errors, clarify responsibilities, and improve outcomes like speed, quality, and customer value.

What are the 5 steps of process improvement?

A simple 5-step version is: (1) define the problem and goal, (2) map the current process, (3) identify root causes, (4) implement improvements, and (5) measure results and standardize what works.

What are the 7 steps of the improvement process?

A practical 7-step cycle is: identify the process, map the “as-is,” analyze inefficiencies, develop strategies, implement changes, monitor KPIs, and standardize the improved way of working.

What are some examples of process improvement?

Common examples include automating repetitive tasks, streamlining approvals, improving quality checkpoints, reducing team handoffs, and building simple KPI dashboards to guide decisions.

What are the pillars of process improvement?

Most organizations succeed when they combine four pillars: clarity (documented processes and roles), capability (skills and methods), measurement (KPIs and feedback), and adoption (tools and routines that make the improved way easy to follow).